Cutting Time on Drill Stem Testing with FLOW-SURE MC™.

30th October 2017

Metrol’s FLOW-SURE MC™ can potentially save weeks of testing time in DST operations.

The in-flow valve technology recently proved invaluable during testing activities on a vessel testing in deepwater. The client used our FLOW-SURE MC™ valve to successfully test a two-zone well, simplifying operations and saving valuable rig time.

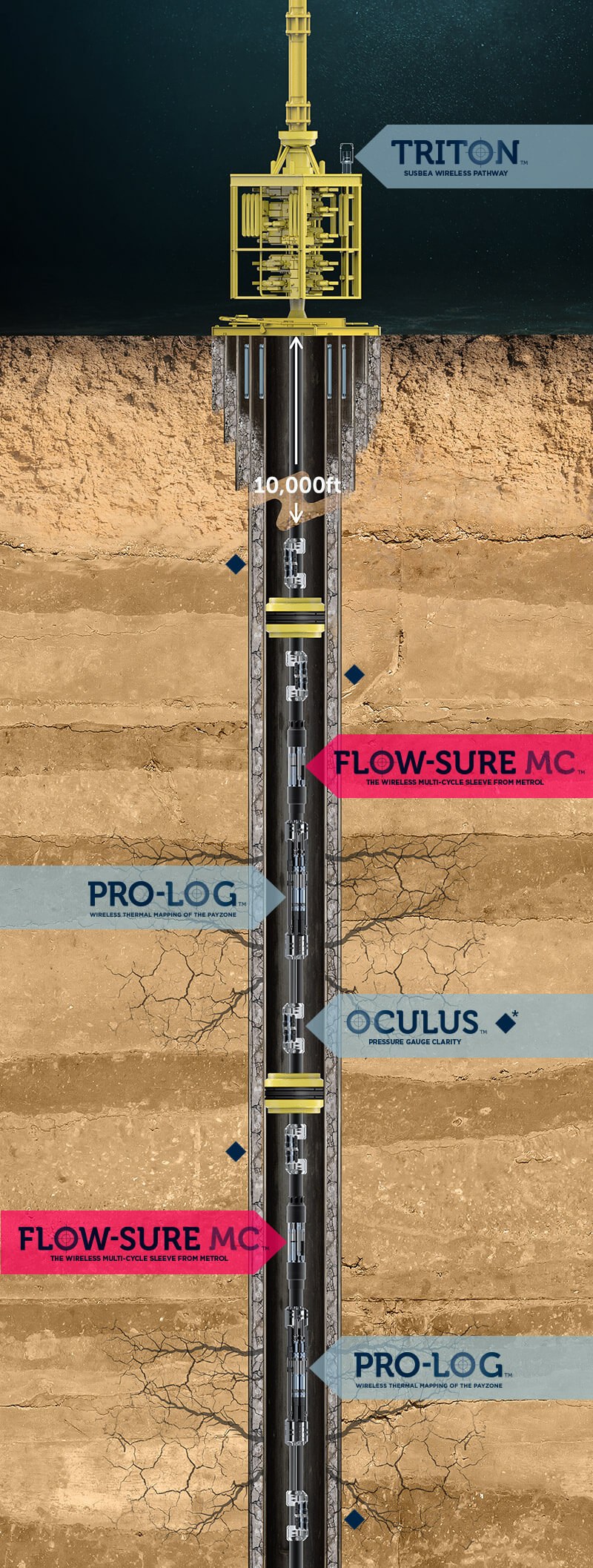

The well had been pre-perforated and suspended with kill-weight brine prior to running the test string. Two FLOWSURE valves per zone were run in hole, on a test string populated with OCULUS™ gauges, ORIGIN™ samplers and PRO-LOG™; the lower zone was isolated with a permanent packer and stung through with the string isolating the upper zone with a retrievable packer.

Initial flow surges were performed on each zone using the FLOW-SURE valves prior to a full well-testing sequence. In total, 19 individual valve movements were performed over 43 days, with each valve function verified at surface directly and wirelessly using in-built electronic proximity sensors.

With the FLOW-SURE MC™ enabling multi-zone testing including options to co-mingle, Metrol is setting new standards in testing capability, efficient valve control and data collection.